shoulder effect tensile testing machine|tensile testing equipment : distributors Tensile testing machines play a vital role in evaluating the strength and durability of materials across industries. Whether it’s determining the tensile strength of metals, plastics, . web3 dias atrás · Charlie. O seu concierge. Descubra apartamentos equipados e mobiliados em prédios prontos para te receber! Uma nova forma de hospedagem que une conforto de .

{plog:ftitle_list}

Resultado da 23. 36. 44. Listado de premios. Comprobar mis aciertos. Histórico de resultados del sorteo de Quini 6. Últimos resultados de los sorteos .

ZwickRoell tensile test machines, including the zwickiLine, ProLine, AllroundLine and E-series machine (tensile testing machine for large test forces starting at 330 kN), are specifically designed to meet customer requirements based on testing capacity, types of material, .Tensile test on metallic materials according to standard ASTM E8 and ISO 6892-1 with AllroundLine materials testing machine and makroXtens extensometer. Tensile testing machines play a vital role in evaluating the strength and durability of materials across industries. Whether it’s determining the tensile strength of metals, plastics, .Titan is a universal testing machine for tensile and compression testing, which has been designed for accuracy, efficiency and ease of use. Tensile testing .

This guide will introduce you to the sophisticated world of tensile testing machines, focusing on their types, functionalities, and the relevant standards like ASTM D638 and ISO 527-2, particularly highlighting how .the Poisson’s ratio, the bulk modulus, and standards for the tensile test. Finally, we will present values of material properties obtained from the tension test for some engineering metals and polymers. 1.1 Specimens and Testing In the time-independent tensile test a sample of the material called specimen is slowly Tensile tests are used to determine how materials behave under tension load. In a simple tensile test, a sample is typically pulled to its breaking point to determine the ultimate tensile strength . The eXpert 1000 series servohydraulic testing systems are widely used to test metal products at very high load capacities. The ASTM E8 configuration includes wedge grips and an axial extensometer and the .

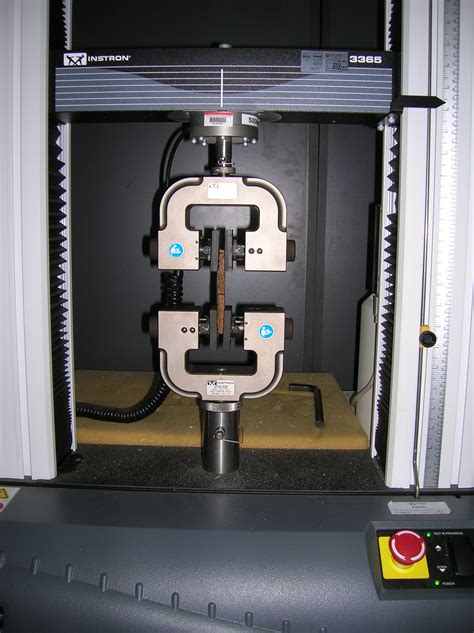

The tensile test is conducted by use of a tensile testing machine or universal testing machine; the latter can be used for both tension and compression tests. In tensile testing, the specimen is firmly held in place by grips of the testing machine (see Fig. 3.4). One end of the specimen is held firm, whilst the other end is pulled by applying a . The purpose of tensile or mechanical testing is to measure the effect of force on a particular material or component, or on the adhesive or fastener that bonds two materials together. Modern universal testing machines (UTM) offer additional capabilities, including proof or creep testing, compression loading, flex or bend loading, and cyclic testing to name a few.procedure to determine if seat belt assemblies with load limiters can meet the force criterion in one test when using stroke-limited machines. All assemblies tested under the conditions of no webbing on the spool or minimal . Table 5. Upper Torso Loop (Shoulder Belt) Tensile Test Results ... 12 Table 6. Pelvis Loop Test Head Rotation .In a Tensile testing machine, designed for this type of testing, data is obtained and computed throughout the process, thus allowing for further analysis of the information regarding the material used. . However, for large deformations (regions of uniform and non-uniform plastic deformation of the tensile curve), the effect of the system’s .

Extensometry is the science of the measurement and analysis of changes in a materials linear dimensions during tensile testing. Skip to content. About; News; Articles; . could be the gauge length setting device is stuck and does not allow the knife edges to open after you start the test. If you can tell me the machine type / extensometer . Threaded shoulders and grips also assure good alignment, but the technician must know to thread each shoulder into the grip at least one diameter's length, otherwise the threads can strip before the specimen fractures. . Additionally, specialized tensile creep testing equipment may include incorporated high temperature furnace components to . Tensile testing is a widely used method for evaluating the mechanical properties of materials under tension. When conducting a tensile test, several parameters are measured to understand the material's behavior under stress. The three primary parameters measured in a tensile test are load, elongation, and strain.

In the tensile test according to ASTM D638, various typical characteristic values are determined which describe the essential mechanical properties of a molding compound or a specimen machined from a defined area of a component:. Tensile stress: force related to the initial cross section of the specimen; Strain: change in gauge length with reference to the initial gauge-length

tensile testing tools

Starting in the late 1940s, extensive tensile (off-axis) testing (Erickson & Norris, 1955; Werren & Norris, 1956) on glass fiber reinforced polymer (GFRP) sheet panels in different directions with respect to the fiber orientation were performed on non-tabbed dogbone specimens to determine the directional properties and were compared to analytical solutions for the .Milling or grinding the dogbone samples minimizes the effects sample preparation may have on the results. Tensile Test Procedure. The gauge length is the reference length used in the elongation calculations. Depending on the test standard, the gauge length is either 2 inches, 80 mm, or 50 mm. Multiplying the width and thickness within the gauge .Tensile testing machines must be selected based on several factors. If you are upgrading quality and functionality, or have decided to move materials testing in-house, you want to make sure that you are not buying a machine that won't meet your requirements. . The shoulder areas must be ample enough to permit a firm grip by the testing .

How do different specimen geometries affect tensile test results? Tensile test results include the ultimate tensile strength, yield strength, Young’s modulus, ductility, and the strain hardening exponent. All these properties can . Friction stir welding (FSW), especially high-speed FSW, was introduced to provide an optimum welding method for ultra-thin Al6061-T6 plates that would improve their mechanical properties. The influence of the shoulder geometry and clamping distance on the joint forming, microstructure evolution, and mechanical properties of a 0.8-mm-thick FSW Al6061-T6 . The tensile testing was conducted to check the strength of the welds using Intron 5500R machine at a cross head speed of 2 mm/min. Tensile testing procedure and specimen dimensions used for testing are shown in .All tensile testing was performed in an Instron Model 1125 electromechanical testing machine. After all mechanical testing had been performed, one of the two failure surfaces of each specimen was prepared for observation with scanning electron microscopy (SEM). During this process the complete failure sur-

Fatigue is defined as the effect of repeated application of stress to the material. Testing for fatigue is important because its development on the material is more insidious. . Depending on the tensile testing machine?s class the unit can either be a bench top or floor standing model. The higher the class, the more complex are the testing . Tensile testing machines work by grasping the test sample then applying a load until it deforms or breaks. Some examples of these machines are load cells, grips and extensometers. . Discover the Ultimate Shoulder Length shoulder shaggy haircuts Ideas for 2024 Han October 26, 2024 Why Do Mexicans Love the Edgar Haircut? Exploring the Trend . This may result in damage to the tensile test apparatus. Non-contact extensometers avoid this problem by using video or lasers to conduct tensile testing. This avoids the risk of damage even when the sample reaches breaking point. Laser extensometers work by illuminating the sample with a laser after it has been loaded in a tensile test machine. Setup. The tensile test is one of the most important testing methods for characterizing or obtaining material parameters. In the tensile test, for example, it is determined which load a material can withstand until it begins to deform plastically (yield strength) or under which maximum load the material breaks (tensile strength).The tensile test can also be used .

Tensile tests are performed on universal testing machines, also known as tensile machines or tensile testing machines. These machines consists of a single or dual column frame equipped with a load cell, testing software, and application-specific grips and accessories such as extensometers.Universal testing machines come in a wide variety of force capacities and can . Prototype and candidate materials are also typically produced in small quantities due to resource and equipment constraints. Being able to perform multiple tests on a finite amount of material is thus advantageous and economical. . Tensile testing was performed using a Kammrath & Weiss Tensile Module (KW) equipped with a 500N load cell .3.2 Testing Machines There are many different types of testing machine available. Some are designed to perform one type of test, for example, tensile, while others are of the 'Universal' type and as such are suitable for uniaxial testing in both tension and compression and also for three-point bend tests on beam type test-pieces.

tensile testing software

3. INTRODUCTION A universal testing machine, also known as a universal tester, materials testing machine or materials test frame, is used to test the tensile stress and compressive strength of materials. It is named after the fact that it can perform many standard tensile and compression tests on materials, components, and structures.The tensile test on thin plastic films according to ASTM D882 is usually carried out on a zwickiLine 500 N single-column universal testing machine due to the low breaking forces. For specimens with a grip-to-grip separation L = 250 mm, which are favored for modulus determination, it may be necessary to use an extra high single-column load frame from the .

tensile testing machine manual

tensile testing machine for metals

webTry online slot machines for fun or for real cash on Mason Slots casino. New players can get 50 free spins bonus.

shoulder effect tensile testing machine|tensile testing equipment